-

SPG Conveyor Systems a Leading UK Belt Manufacturer

Highly experienced conveyor manufacturer

Standard & bespoke belt conveyors for your specific applications

24 Month warranty as standard*

Expert installation and maintenance services available

Quick deliveries often available

Proven reliable products with high quality customer service

Belt conveyors manufactured in the UK, to your specifications

SPG Conveyor systems are a UK leading manufacturer of proven reliable belt conveyors with over 30 years experience. Our belt conveyor are ideal as stand alone units or for integration into a wider conveyor system or other bespoke machinery. The wide range of equipment, built by SPG uses only quality components ensuring you receive a reliable conveyor. Which is built to suit your specific requirements and of course at a competitive price.

Why SPG?

As an ideal UK manufacturing partner, producing reliable, durable belt conveyor products, to suit your application. SPG Conveyor Systems, build both standard and bespoke conveyor equipment – ensuring the best solution for your precise needs. Which is backed up by our UK service personnel and manufacturers warranty.

With a wealth of experience within a wide range of industries and applications. Most products have options for mild steel, stainless steel or aluminium construction. with most products using proven designs to suit all product sizes and materials. SPG Conveyor systems provide a long lasting, cost effective and reliable solution.

All of our conveyors come with an operation manual, UKCA / CE marked where required & 24 month warranty for your peace of mind, get in touch today and receive a free quote!

Phone: 01482 363445 Email: sales@conveyorsystems.co.uk

Below is a brief overview, for extra technical details please contact us

| End Roller Diameter: | From 25mm to 200mm - To suit your loads and application |

| Drive Type: | Geared motor or Drum Motor |

| Drive Position: | Shaft mounted, Underslung or End Drive |

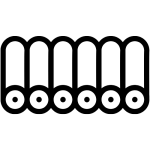

| Belt Type: | 1ply PU, PVC or silicone (industrial or food grade) 2ply PVC (industrial or food grade) 2ply Rubber Other belt options available please contact sales |

| Frame Material: | Mild Steel Stainless Steel |

| Conveyor Finish: | Powder Coated Paint (RAL5010 as standard) Stainless Steel (2B) |

| Conveyor Widths: | 80mm to 2000mm |

| Conveyor Loading: | Please contact sales to discuss your options |

| Support Detail: | Welded 'H' section (+/- 50mm) |

| Optional Extras: |

|

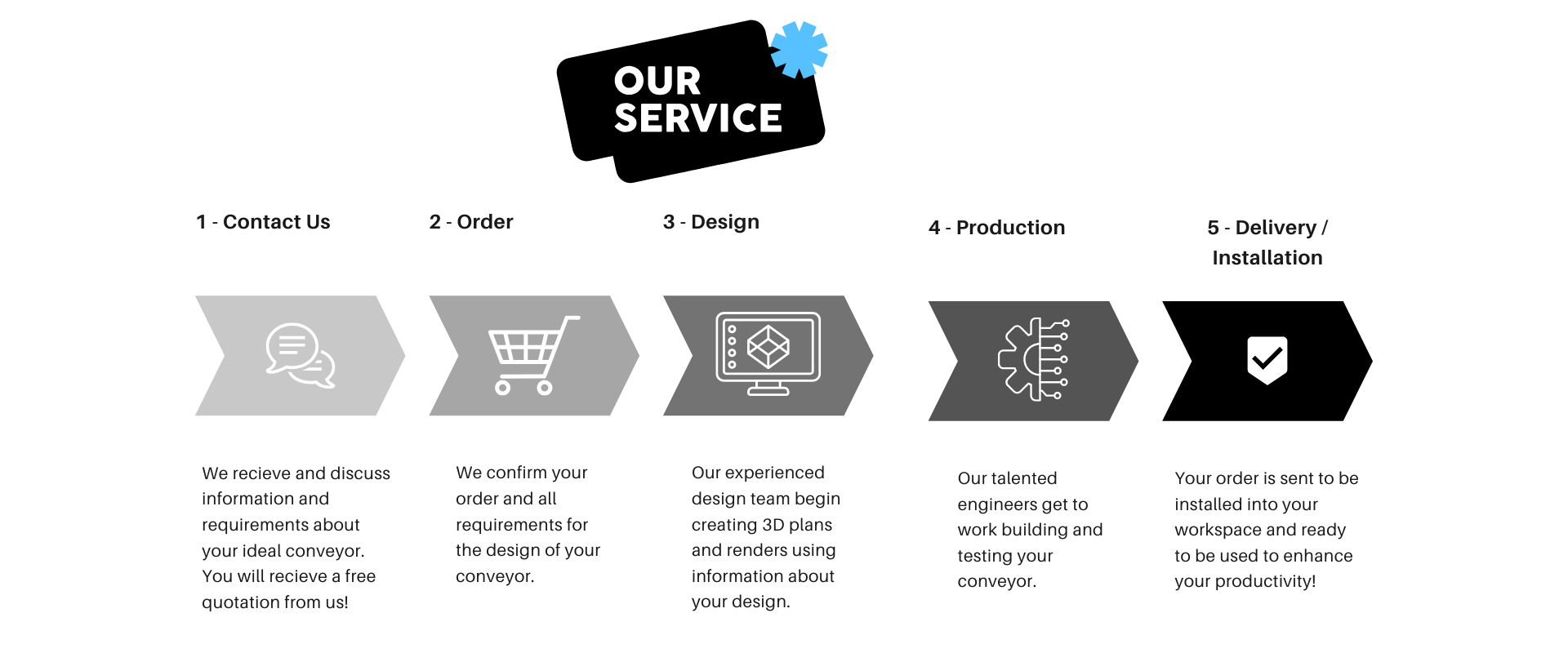

OUR SERVICES

We offer a variety of services to our clients

Fast Delivery

Fast delivery offered across the UK for all standard conveyor modules

Helpful Sales & Support Team

Our sales team work closely with our engineers and installers to ensure you're supported every step of the way

Competetive Pricing

We will always offer you our best price possible and work with you to suit your budget

24 Month Manufacturers Warranty

For your peace of mind, we offer this manufacturer's warranty on all conveyor modules

High Quality Components

The highest quality components used are manufactured by industry leaders including Interoll and Ammeraal.

Installation & Maintenance Services

Conveyor installation and maintenance options are offered to ensure ongoing optimal performance

Popular Belt Conveyors

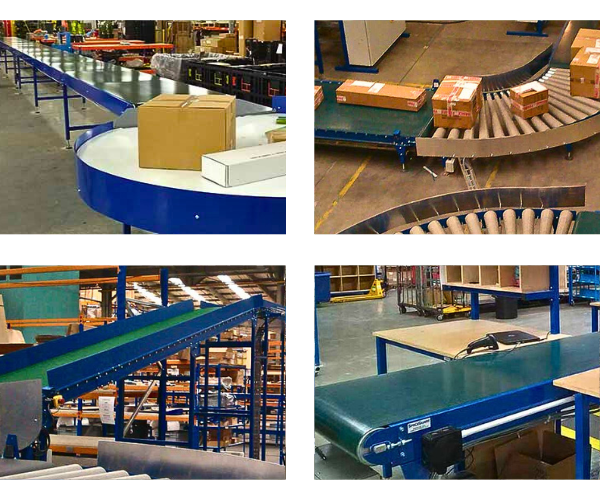

Belt Conveyors Gallery

All conveyors shown below were manufactured for our customers in our UK based factory.

Conveyor Belt Information

Belt conveyor systems designed & built to suit your needs and delivered directly from our UK-based factory

The range of SPG belt conveyor products are designed to offer versatilty, with models and bespoke designed in use within almost every industry and application imaginable. At SPG Conveyor Systems we take the headache out of the specifying and selection process, our helpful sales team and trusted engineers make sure you get the exact belt conveyors you need for process.

SPG Conveyor Systems is a trusted UK-based conveyor belt manufacturer, producing not only stand-alone belt conveyors for integration but also complete turn key conveyor systems. Our dedicated team has been helping customers by deliverying the exact equipment they required within there specific application for over two decades. From micro belt conveyors to heavy-duty or extra wide belt conveyors, we guarantee that all conveyors are reliable by being designed and built to the highest standards.

Delivery & Installation

Firstly, all equipment will arrive fully UKCA or CE marked and complete with operation and maintenance manuals - we aim to make our equipment especially simple to use, all that you have to worry about is unloading and plugging in.

We have a range of standard conveyors in stock for fast delivery so we can get a belt conveyor to you when you need it most.

Please contact our helpful sales team for a friendly chat about your requirements

Industry Applications

Food Production & Packing

For sorting, transporting, and packing food items we manufacture fully washable hygienic stainless steel belt conveyors that can be used alongside other processing equipment such as inspection tables.

We also manufacture a variety of accumulation equipment including rotary packing tables and plastic modular belt accumulation belts.

Warehouse & Fulfilment Packing & Parcel Transport

SPG Conveyor belts are used to transport packets and parcels of varying sizes and weights with irregular shapes. Along with roller conveyor which generally used for flat-bottomed items.

Belt conveyor systems can also be incorporated into your existing packing lines or warehouse conveyor systems and if required design a new fully bespoke conveyor system to suit your requirements.

Product Assembly and Manufacturing

At SPG we manufacture belt conveyors to fit into your existing assembly or process lines, or design new process assembly line and transport conveyor systems as required for your application. Belt conveyors are commonly used for linking machinery as well as for infeed and outfeed systems. Factory conveyor belts are ideal for moving materials and components as well as waste products. For moving large and heavy items, we can manufacture heavy-duty conveyors.

Mezzanine Belt Conveyors

Belt conveyors can be used for inclines and declines as well as for transport between floors or mezzanines. Our team have in-depth experience of designing, manufacturing and installing mezzanine conveyor systems and can visit your site to gather the required information, please see the mezzanine conveyors page for more information.

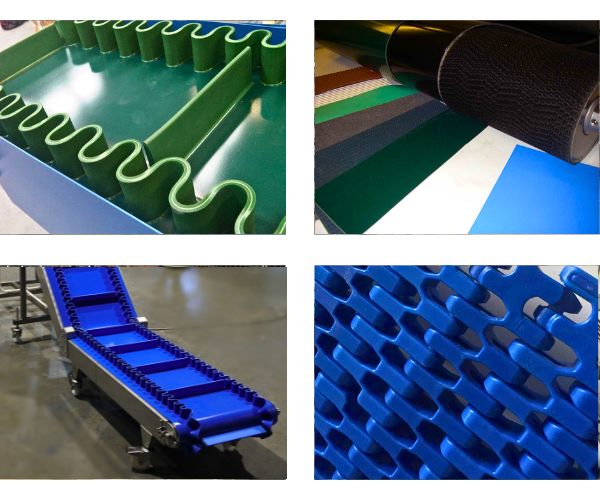

Conveyor Belt Materials for all applications

Conveyor belting material comes in many varieties with different colours, thicknesses, materials, and features. The most common belt conveyor materials are rubber, silicone, PVC, plastics, and chain belting. Secondly, belt types have significantly increased benefits such as being grip-faced, cut-resistant, or having improved tracking. Our team can help you choose the correct belting material and belt width and length to suit your application.

- Sidewall Belting

- Various Materials & Colours

- Flighted Belts

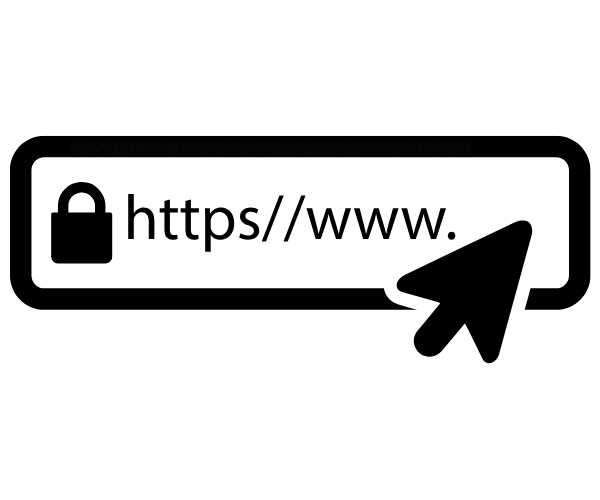

- Plastic Modular Belting

Get a FREE Belt Conveyor Quote today

We are a leading UK manufacturer of Belt Conveyors

Email sales@conveyorsystems.co.uk with your enquiries

Belt Conveyors FAQ

Get all the answers to your questions about conveyor belts, as well as advice on how to choose the correct type for your application.

A belt conveyor is a mechanical system designed to transport materials or goods from one location to another along a continuous loop of material, known as the conveyor belt.

They were invented to increase efficiency in areas of manual transportation of goods. Manual labor was intensive and time consuming with many errors, so belt conveyors automated the process, allowing for continuous and consistent movement of items. Reducing manual handling.

BED: The Steel Section to belt sits on

BED LENGTH: The length of the steel section

BED WIDTH: Overall width of conveyor frame

BELT: The moving surface of a belt conveyor

BELT LENGTH: Overall length of belt used to wrap around all the pullies

BELT WIDTH: Width of moving surface

BELT SCRAPER: Blade or brush fitted to underside of conveyor to remove debris

BELT SPEED: Conveyor speed. The length of belt which passes a point within a predetermined time

BRAKE MOTOR: A motor with a electromagnetic lock on it to stop the belt firmly when stop button is pressed.

(Normally fitted to Mezzanine conveyors or conveyors used where access is requried)

CASTERS: Wheels fitted to the conveyor to move conveyor around (NOTE: leg design is important to consider when using)

CEILING HANGER: Support structure fitted used when fitting conveyors to a ceiling

CENTER DRIVE: When the motor drive unit is positioned nominally in the center of a conveyor (Often used on longer conveyors)

CHAIN GUARD: A Physical barrier fitted around the moving chain and sprockets to protect from access

CHUTE: Often used on inclined conveyors to deposit product into, to load belt

CLEAT: an attached fitted or welded onto the belt to push parts up the belt

CROWNED PULLEY: A machined taper on the tubes of the end roller to aid with keeping the belt running true

DECLINE CONVEYOR: A down hill travelling conveyor

DEGREE OF INCLINE: The angle of slope of the conveyor - on an inclining conveyor (A lot depends on belt types, attachments and

products conveyed)

DELTA: Wiring option for 3 phase motors - used when running motors through single phase inverters

DISCHARGE END: Outfeed end of conveyor

DRIVE: The motor or assembly type used to power the belt

DRIVE PULLEY: The pulley which has power going to it to move the belt

DRUM MOTOR: A Drive type where the motor is enclosed within the tube of the pulley

EMERGENCY STOP BUTTON: Electrical device used to stop conveyor in emergency - (Requires additional control)

EMERGENCY STOP PULL CORD: A Wire which runs the length of the conveyor used to stop conveyor in emergency - (Requires additional

control)

FLOOR SUPPORTS: Structure used to support conveyor whilst floor mounted

FLOW: The direction of travel on the conveyor

FPM: Feet per minute (Speed)

GATE: A section of conveyor which can be opened for access

GEARBOX: Normally fitted to a motor, selected combination denotes what the conveyor speed will be

GEARED MOTOR: A means of powering the conveyor - combining a gearbox and electric motor

GUIDE RAIL: Members used to stop items falling off the belt

HORIZONTAL FLOOR SPACE: The length of floor required for the conveyor

HORSEPOWER: A measure of time and rate to do the work (Normally used electrically 1 HP = 0.75kW (Nominally))

HZ: Electrical terminology used around sine wave frequency - can be altered through inverters to change speed and torque outputs

INCLINED CONVEYOR: Up hill driving conveyor

INCLINED CONVEYOR LENGTH: The length of the uphill section

INFEED END: The loading end of the conveyor

INVERTER: Electrical device often used to adjust speeds and torque of conveyors - Can be used to turn 1ph 230 to 3ph 230V

kW: How powerful the motor is

LACING: A mechanical fastener used to join both ends of the belt

LAGGED PULLEY: Material bonded to a pulley to increase friction to help drive

MOTOR: Normally electrical - an item which provides a rotating power to an output shaft

NIP GUARD: Fixed guarding used around nip points or drawing in points on belt conveyors

NOSE OVER: A conveyor section going from inclined to horizontal

OVERALL LENGTH: The total length of the conveyor

OVERALL WIDTH: The total width of the conveyor

PHOTO ELECTRIC CELL (PEC): An electrical device used to sense products (Often used to stop / start belts automatically

POP OUT ROLLER: Often fitted to the end of a belt conveyor - when the conveyor is running up to a fixed surface or gravity roller conveyor.

POWERED CONVEYOR: The conveyor is driven and doesn't require products to pushed along

POWER FEEDER: A section of horizontal conveyor - normally at the bottom of an incline conveyor

PULLEY: Either driven or idler roller - mounted to provide means to return and power belt

REVERSIBLE: Conveyor is capable of driving in both directions

SHAFT MOUNTED: Normally referring to where the Geared motor is mounted

SLIDER BED: Normally same as Conveyor bed

SNUB ROLLER: Roller used to increase the wrap around the drive rollers

SUPPORT: Structure used to mount the conveyor at required height

TAIL PULLEY: Normally used to provide means to return the belt

TAKE-UP: Assembly used to provide tension and tracking to to the belt

TOTAL LOAD: The overall weight of items going on the conveyor

TRACKING: Term used in regard to keeping belt running true

TRUE TRACK: Term used to addition of guides fitted to the underside of belt to mechanically keep the belt running true

Generally consist of a loop of belting material that is placed around two or more rollers, with at least one of these rollers, also known as pulleys or drums, being motor powered so it rotate under its own power. As the powered roller(s) spins, the friction between the motor and the belt causes the belt to be pulled in the direction that the motor is turning. The result being the belt continuously rolls over and around the rollers.

There are many types of belt conveyors each made to suit specific applications, below you can find a list of different types of conveyor belts and their uses.

Standard Flat Conveyor

These are the conveyors you will commonly see at supermarket checkouts, they're the most simple type of belt conveyor and ideal for A to B transport on a flat level surface.

Inclined Conveyors

Inclined belt conveyors are used for transporting items upwards, either to create a bridge in a conveyor system, to feed materials into machines, or to carry items to and from upper floors or mezzanines. They often use flights or grip face belts to help stop materials from falling back on the conveyor.

Sandwich production Conveyors

Sandwich belt conveyors consist of two belt conveyors running parallel and face-to-face so the items to be transported are 'sandwiched', between them and held in place by gentle pressure. Confusingly, sandwich conveyors are also a type of conveyor that is made specifically to help people make sandwiches.

Trough Conveyor

Trough belt conveyors have flexible belts that are folded into a trough U shape using a series of rollers on the bottom and sides to prevent spillages. They are used for transporting fine or lightweight materials, aggregates, soil, and rubble.

Pipe Conveyor

Similar to trough conveyors, they also have rollers around the undersides of the belt to shape the belt, though this time the belt is folded around into a closed circle O shape to create a pipe, again these are used for loose materials.

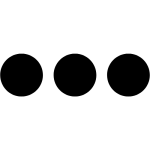

Modular Belt Conveyor

Modular belt conveyors have a belt consisting of rigid plastic interlocking modules that make the belt much stronger whilst still allowing the belt to curve and flex. They are also positively driven by sprockets which means they do not slip.

Slat Conveyor

Slat conveyor belts are similar to modular belts however the slats are linked in a single chain and do not have the same side flexing capabilities as modular belts. They are ideal for transporting cans, bottles, and aerosol canisters.

Working With Us

SPG Conveyors are used daily by a wide range of third-party logistics, manufacturing, food production, and product assembly businesses in the UK.

We offer tailored solutions to suit our customers' needs:

- Warehousing & Logistics Transport Conveyors

- Factory & Production Line Conveyor Belts

- Packing Lines

- Food & Drink Conveyor Belts

- Conveyors built for integration within other equipment

- Subcontract conveyor manufacturing

- Happy to work with resellers and OEMs

If you need modular conveyors for your business then please contact us by phone, email, or try out the live chat feature for a free no-obligation quotation.

Call:01482 363445

Email: sales@conveyorsystems.co.uk

Our Clients

Contact Us for a Free quotation

Contact us today to get your conveyor project started

Custom designed conveyor solutions

In-house design team

Helpful customer support team

01482 363445

We manufacture Belt Conveyors to suit your needs

Each belt conveyor can be delivered fully assembled or installed on your site by our team. They are also available for integration into another conveyor system or other customer machines. Full white label service is available for resellers. All conveyors are backed by our 24 month warranty*, so you can be undoubtedly assured of a well built, reliable conveyor. Designed and built to suit your specific requirements.

- Transport Belt conveyor

- Positively Tracked Conveyors

- Modular Belt Conveyors

- Slat Conveyors

- Mobile Conveyors

- Mezzanine Incline Conveyors

- Extra Wide Conveyors

- Stainless Steel Conveyors

- Swan neck and nose over elevators

- 24 Month Warranty

- Competitive Pricing & Quick Deliveries

- Supplied With CE or UKCA and OEM Manual

- Built Using Quality Components

- UK Manufacturer

- Available fully wired and installed or for integration

- White label service available for resellers

- Installation Service available

- Wide choice of belt types and finishes

We also design & build other types of conveyor systems:

ROLLER CONVEYORS

Find us on Various Platforms

Supporting our customers & their products

SUPPORT

Our excellent customer service team are available for ongoing customer support

DELIVERY

Conveyors delivered fully wired ready for work or installed by our team across the UK

WARRANTY

All products come with two year warranty & supplied UKCA / CE marked with associated manuals.

SERVICE

All products come with service packages to ensure optimal performance and ongoing reliability.

4.5

We had two bespoke desks made for our warehouse. Customer service from Ellie was amazing from start to finish - really attentive and quick to reply to any queries. I also feel like Spaceguard pulled out all the stops to deliver within a much shorter time period than the quoted lead time. Would highly recommend and would definitely use them again. Spaceguard were amazing from the start. They took the time to listen to our requirement's and see our way of working. Once this was seen they designed our new ecom packing tables from the bottom up. The 3D modeling was great, as we were able to see the design and easily make any tweaks before approving. Once approved we were kept informed of the progress and installation was fitted around our needs and done very professionally. Would highly recommend them for your projects. 5* service Second time using Spaceguard and we couldn't be more pleased with their team. From placing an order to installation the process was incredibly smooth. We 100% recommend their services.

www.spaceguard.co.uk

14 Reviews

Bespoke Warehouse Furniture

Spaceguard were amazing from the start

5* service