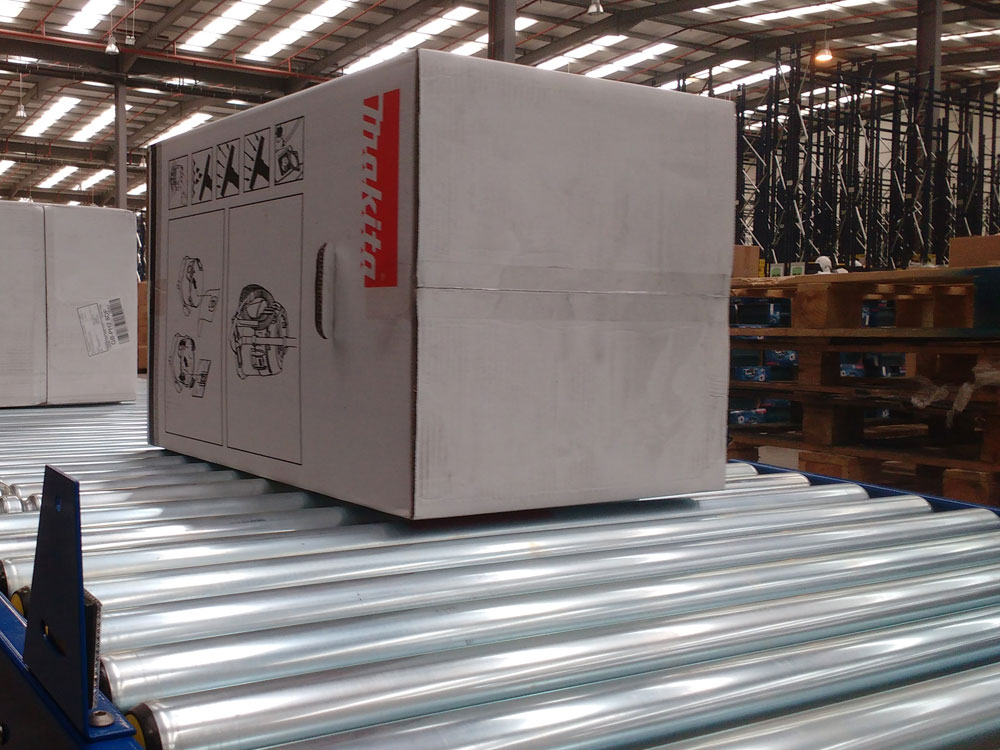

Powered warehouse roller conveyor

Understanding Roller Conveyors: Enhancing Efficiency in Warehousing and Manufacturing

What is a Roller Conveyor?

A roller conveyor is a mechanical system designed to transport materials or products efficiently from one point to another. Widely used in warehousing, manufacturing, and distribution industries, roller conveyors come in various forms but all share the common goal of moving objects with minimal effort.

How Roller Conveyors Work

The basic principle behind roller conveyors is simple: items placed on the rollers move in the direction the rollers spin. Rollers can be powered by gravity, manual push, or electric drives. Without the rollers spinning, the conveyor functions like an ordinary table.

- Gravity Rollers: Utilize the weight of the items or a slight incline to move products.

- Manual Push: Items are manually pushed along the conveyor.

- Electric Drives: Rollers are driven by motors or drive shafts.

Types of Roller Conveyors

- Gravity Roller Conveyors

- Move items using gravity or manual push.

- Ideal for lightweight items and short distances.

- DC Powered Roller Conveyors (24v)

- Motorized rollers linked by polyurethane bands.

- Excellent for automation and energy conservation.

- Ideal for zero-pressure accumulation.

- Lineshaft Roller Conveyors

- Rollers are connected to a central shaft via bands.

- Driven by a motorized shaft, suitable for lighter loads.

- Chain-driven Roller Conveyors

- Heavy-duty rollers connected by chains.

- Suitable for transporting heavy items without slippage.

- Flexible Roller Conveyors

- Adjustable and portable.

- Can bend around corners and are ideal for limited spaces.

Luckily a simple solution for carrying oddly shaped items, things of varying sizes and weights, or lightweight products is to use a belt conveyor.

Choosing the Right Roller Conveyor

Selecting the right roller conveyor depends on factors like item weight, size, speed, direction, and budget. Each type has unique advantages suited for specific applications.

When to Avoid Roller Conveyors

Certain situations may require alternatives to roller conveyors:

- Soft and Squishy Items: May sag and slip between rollers.

- Extremely Fragile Items: Risk of damage from collisions and jostling.

- Small Items: Can slip through gaps between rollers.

- Lightweight Items: May not generate enough friction for movement.

For these scenarios, belt conveyors may be a better option.

Contact Us

Need help choosing the right roller conveyor? Contact our experts today for tailored advice to optimize your conveyor system.

By understanding these key aspects, you can choose the best roller conveyor system for your business needs, enhancing efficiency and throughput in your operations.

01482 363445

Leave a Reply