Why Smart Businesses Are Investing in Conveyor Systems to Save Time and Money

So, how can conveyors reduce labor costs? In today’s competitive business landscape, efficiency is everything. Companies across industries are constantly looking for ways to reduce costs, streamline operations, and increase productivity. One of the most effective solutions? Conveyor systems.

The Hidden Costs of Manual Labor

For businesses relying on manual labor for material handling, there are significant ongoing expenses—wages, training, turnover, and human error all add up. While a dedicated workforce is invaluable, certain tasks can be automated for greater efficiency without compromising quality or reliability.

A well-designed conveyor system can move products faster, more accurately, and with fewer disruptions. This means companies can process higher volumes in less time, reducing delays and increasing output—all while cutting down on unnecessary labor expenses.

How Conveyor Systems Improve Productivity

- Speed & Consistency – Unlike human labor, conveyors work at a constant, reliable pace, ensuring smooth production without fatigue or variation.

- Reduced Errors – Automated systems minimize misplacement, damage, and lost items, improving overall workflow.

- Less Downtime – With fewer stoppages and manual handling errors, businesses can maintain a continuous production cycle, improving order fulfillment times.

Choosing the Right Conveyor System for Your Industry

Different industries have unique requirements, and choosing the right conveyor system can significantly impact efficiency and cost savings. Here are some of the most commonly used conveyor types and their benefits:

- Belt Conveyors – Ideal for transporting bulk materials or packaged goods over long distances, commonly used in manufacturing, food processing, and e-commerce warehouses.

- Roller Conveyors – Suitable for heavy loads and palletized goods, making them ideal for distribution centers and logistics hubs.

- Modular Belt Conveyors – Great for handling irregularly shaped products, often used in pharmaceutical and food industries.

- Chain Conveyors – Designed for extreme conditions and heavy-duty applications, often found in automotive and industrial manufacturing plants.

- Incline/Decline Conveyors – Used for moving products between different levels, perfect for multi-level warehouses or assembly lines.

Customizing Your Conveyor System with Add-Ons

To maximize efficiency, businesses can customize their conveyor systems with additional features, such as:

- Automated Sorting Systems – Ideal for e-commerce and distribution centers to streamline order fulfillment.

- Weighing & Scanning Integration – Helps businesses track inventory and ensure accurate shipping weights.

- Hygienic Washdown Features – Essential for food production facilities requiring frequent cleaning.

- Adjustable Speed Controls – Offers flexibility to adapt to different operational needs.

- Smart Sensors & AI Integration – Enhances automation by detecting bottlenecks and optimizing performance in real time.

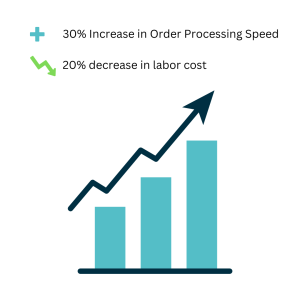

The Cost-Saving Benefits of Automation

While the upfront investment in a conveyor system may seem substantial, the long-term savings far outweigh the initial cost. Let's learn more about how conveyors reduce labor costs. Businesses can experience:

- Lower Labor Costs – Reducing dependency on manual handling means fewer staff hours spent on repetitive tasks.

- Decreased Injury Risks – Workplace injuries can be costly. Conveyors take on the heavy lifting, reducing strain and liability.

- Energy Efficiency – Modern conveyor systems are designed to use minimal energy, lowering operational expenses.

Industries Benefiting from Conveyor Systems

Many industries have already discovered the advantages of automation. Businesses in manufacturing, warehousing, e-commerce, and food production have successfully implemented conveyor systems to maximize efficiency while keeping costs under control.

Future-Proofing Your Business

As demand grows and competition intensifies, businesses must adapt or risk falling behind. Investing in conveyor systems ensures your operations remain scalable, cost-effective, and optimized for the future.

If you're ready to explore how conveyor systems can help your business save time and money, visit ConveyorSystems.co.uk today.

Or contact our expert team via email or phone!